One area that has received heightened attention as of late is the automation of various tasks in the field of engineering and architecture. It is easy to find plenty of material on the subject and you can see people discussing how to streamline design processes, how to simplify and carry out repetitive tasks in a more efficient manner. As a part of the industry, representing the BIM side of things, we are happy to see the greater awareness towards automation and adoption of innovations in our field, which is known to be very slow to change. However, through the discussions with partners, colleagues and the people from this sector in general, we have noticed that more often than not companies choose to rush and aim for giant leaps in adopting automated workflows or take the completely opposite route – they try to play it safe through excessive micromanagement and, thus, moving at a snails pace. In the present highly competitive AEC market, it is essential to maintain proper pace to ensure a natural and fluid adoption of innovations related to BIM adoption.

While the original article on this topic has been shared by our founder on LinkedIn (you can find it here), the relevancy of the topic has not diminished and we have reshared it on our blog with some modifications. We aim to provide the insight to get your company moving onto the right path or at least bring the level of awareness to get your inside discussions started. Like the original article, the content is rather lengthy. For those in a hurry, we have a highlights section at the end.

Time and project quality are interconnected

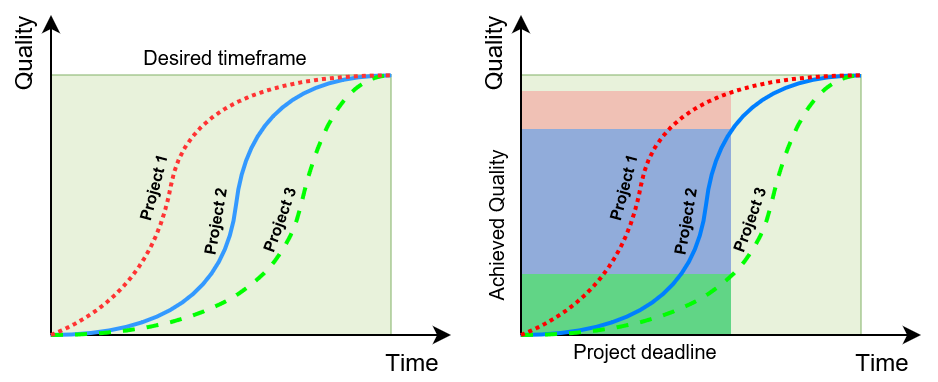

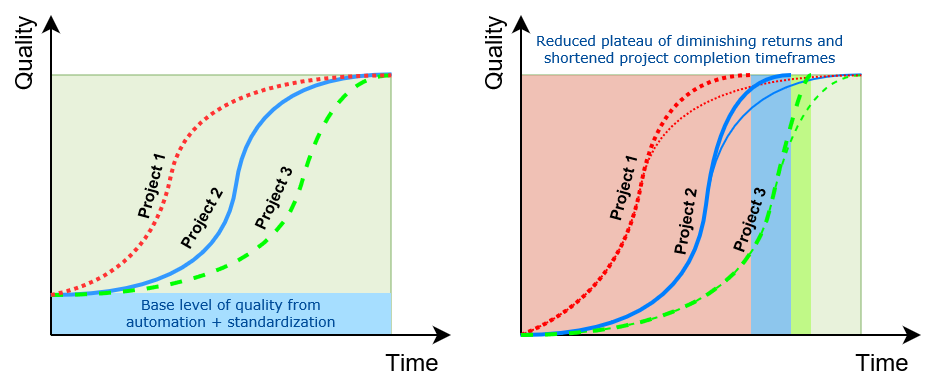

It is no secret, that longer times for project deliveries usually end up with increased project quality, less mistakes and potentially less rework needed. However time is not an infinite resource in the AEC sector, where entire processes can stop, such as construction, if engineers or architects do not deliver their project parts on time. The adoption of BIM has promised many things, among them was greatly reduced time spent on design, yet this promise has been realised only in part. The situation is slightly paradoxical, as time goes by, the amount of requirements to be satified only increases and the regulations are only getting stricter and more numerous, yet the time given to complete projects is only getting shorter and shorter. This push from clients in the AEC sector to deliver more projects, better projects and in less time is one of the core issues today. The reduced timeframes have a significant impact on project quality levels. The illustration below conveys this issue:

In an ideal scenario, the timeframe is long enough to achieve the required quality levels. Let’s take the above illustration, the left side. The green box represents the quality requirements and the time necessary to reach that goal. Three curves, representing three possible project cases are provided. Most projects start off rather slowly and gradually build-up, with the majority of works getting done somewhere in the middle of the process. As the project nears completion, projects often slow down as their complexity has greatly increased by this stage. Some projects may take a significant amount of time to polish and finish up documentation and other design aspects before it can be delivered, other projects can have a very well managed process for delivery and not have a prolonged stage at the end. Now taking the right side of the illustration, there is a new coloured box within the light green one. The right side of this new box represents the stricter design delivery deadline. Now what happens is that if nothing in the design workflow is changed, the shown projects will be at different stages of completion or quality. Since design works must be completed, it is clear that many corners will be cut to meet the delivery deadline. No engineering/architecture company wants to be in this situation, not to mention that no client or contractor wants to be on the receiving end of this scenario.

To ellaborate on the term project quality that we use many times throughout this post, it is not a straightforward metric. In some instances, it can be considerd the quality of the decisions by engineers or architects, the quality of the BIM model in terms of how well it satisfies the client’s requirements. Moreover, it is further defined by things such as lack of mistakes costing resources (time, money, etc.).

The future is difficult to predict, however, we can be sure that time will not slow down and we will not magically receive extra hours in a day. With that being said, people will have their limits on how much they can do within a certain period of time, pressure from

Design and workflow standardisation

Working in AEC sector is a team effort, regardless if your company is an architectural or an engineering consultancy, where can be many teams of various sizes, each working on seperate parts of a larger project that must come together perfectly. In order to achieve that, a set of rules are neccesary that govern how project data moved between teams, what engineering solutions are implemented by each team. While many aspects are already controlled in larger companies, small and medium sized AEC companies often have more liberal views towards this standartisation process and it is natural as company size does affect the design process. Yet, there will still be certain rules. Without standards, every engineer would propose a different solution to the same problem and agreeing on which one to go for would be near impossible.

Standardisation is somewhat controlled and is actually widespread in the industry in a broad sense. Even for BIM, we have standards such as ISO 19650-1 and ISO 19650-2 that aim to govern how we deal with information and data exchange in BIM models. However, this discussion about standardisation is not just about having large scale standards for common project design processes. Every consultancy is unique in their own way, having specific traditions on how they approach certain problems and how they solve them. Some companies specialize only in certain structures, others focus on working more with contractors, others are focused on just architecture. In this post, we want to highlight the standardisation of the described company experience and knowledge on a smaller scale.

Establishing certain standards for how your company approaches things like design of earth retaining structures, bridge, or highrise fascade systems provides certrain boundaries and consistency in your project quality. If working with a contractor, there will likely be numerous requirements for geometry to simplify formworks and limit reinforcement shapes or lengths to make the project more workable. All of this data allows for some level of standardisation at company or project level. Ultimately, they are just certain rules and constraints.

You might be wondering why write so much about things that are common sense. Our experience points to a clear discrepancy between what we hear from engineering consultancy management and working project managers. Often management believes that they have all these standards set up and they have a clear way of how their engineers or architects approach specific tasks, however, actual work is very fragmented and working staff will highlight the opposite. Imagine that three different teams from the same company are working on three bridges on the same highway, relatively close to each other. The obvious expectation is for these structures to be as identical as possible. Yet there are still too many cases when this scenario is not the case.

Our advice is to put everything on paper, refine your company’s approach to design, define preferred reinforcement shapes, describe limits on certain geometries, dimensions, materials and etc. But leave some room for innovation and creativity, depending on your business profile. What might work for an engineering consultancy might create new problems for an architecture focused consultancy.

These rules and contraints will greatly simplify the transition to parametric BIM modelling later on. Without standards it is very easy to get overwhelmed when trying to parametrice certain models, often by attempting to account for too many possible design choices and wasting countless hours on things that will not be used.

BIM model parametrisation

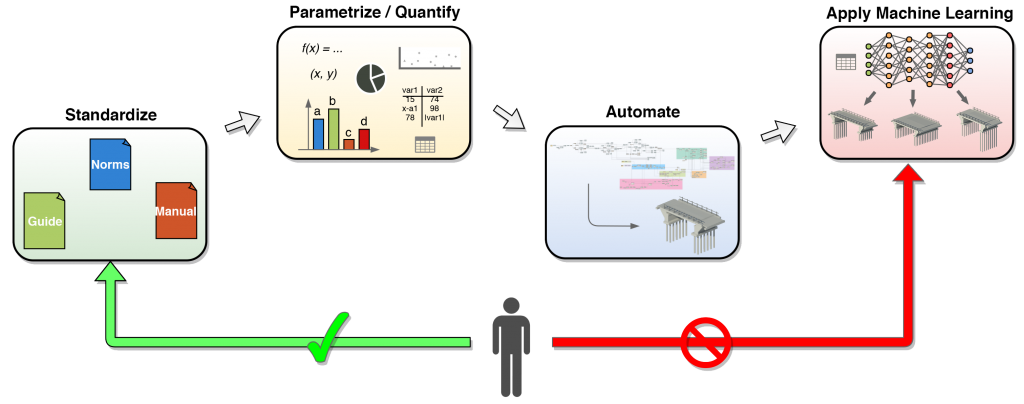

When taking standardisation of BIM modelling to the next level, we approach parametricism, when the set of rules, constraints, best practices established in the previous stage are integrated

As an example, imagine we wanted to develop a tool to automate the placement of piles under a bridge foundation in Revit. The first values we obtain are from the various design codes, such as Eurocode 2, that engineers must follow (depending on the country). Then we define our parameters, in this case, the material and pile diameter can be considered as constant parameters. We can consider that the contract has specified to use 600mm diameter piles and reinforced concrete of C30/37. Other parameters, taken from design codes, such as spacing between piles are similar to variables, as they can vary a bit, but they are dependent on the geometry of the foundation, number of pile rows and number of piles. As for variables, the number of piles, pile depth and the

Parametric modelling has been around for a while and it will remain to be significant for proper automation and application of machine learning methods to engineering and design problems. If your company has set up proper standards and has quantified this information, creating small scale parametric BIM models can greatly boost productivity. With enough parametric models and quanitifed information available, implementation of large scale BIM model automation will be more fluid.

BIM modelling automation

The concept of automation in BIM workflows is often presented in many different forms. Presently, there appears to be a significant focus on applying machine learning or going for generative design approaches. We prefer to call this stage automation. It covers not just BIM modelling or geometry related aspects, workflows can be automated from data, parameter management, automatic scheduling, bill of materials, clash checks, conformity to project standards checks and plenty more cases.

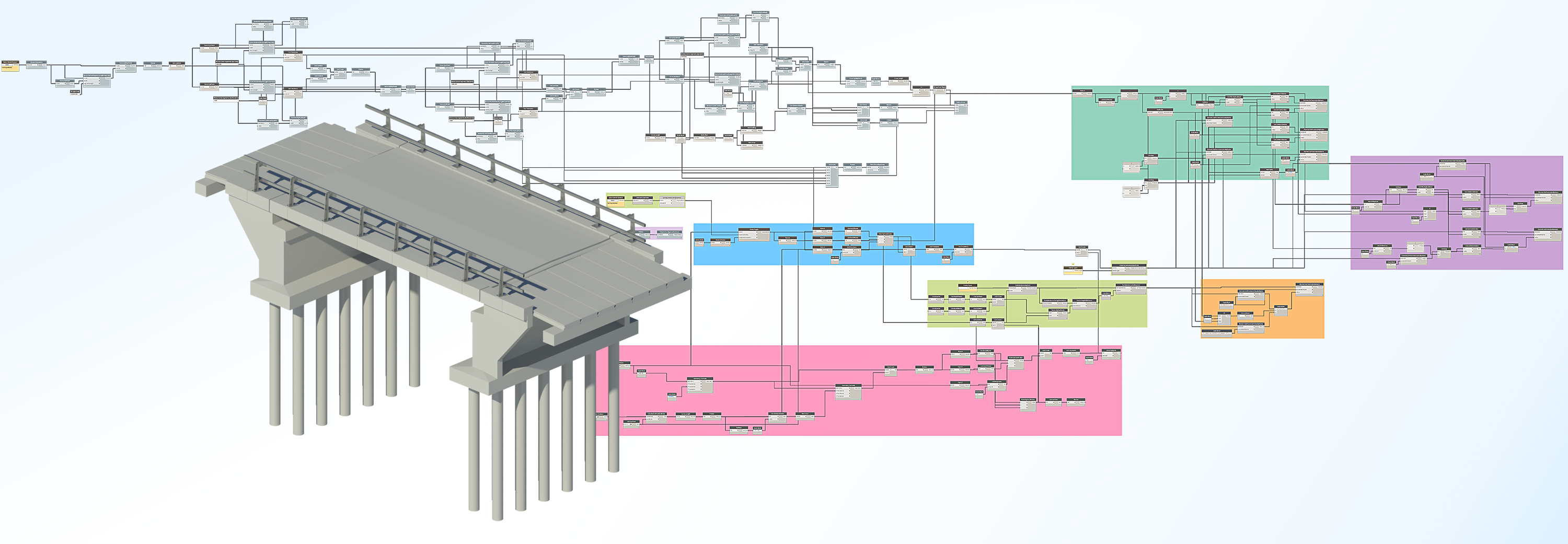

Automation is quite problematic to categorise, we will try to use our practice to groups tools by type. Invoke SHIFT prioritises tools that either extend software capabilities (e.g. for Revit) or automation of repetitive/complex tasks. Tools created to automate certain processes include numbering reinforcement, elements, inserting custom parameters

Generative design can be used for numerous cases, despite most often encountered for various building zoning and interior layout scenarios. The process can be tailored to engineering problems as well, from reinforcement layouts, distribution of elements to meet numerous requirements, such as accoustic barriers along highways, railing systems, tunnel segments and used for many other cases. Generative design tools are often controlled by genetic algorithms, which by themselves are not magical and can take a significant amount of time to produce results that fully satisfy the given criteria do to their nature. Presently, many associate generative design with visual feedback optimal designs, but this is mostly an evolution of results postprrocessing, underneeth, the core algorithms can be implemented without any graphical feedback and that can sometimes produce a speed increase of magnitutes greater than tools such as Autodesk Refinery. Alternatively, if your problem can be formulated and solved by simple mathematical optimisation algorithms may be a better option.

As engineers, we aim for efficiency and will always advise on which approach to select to maximise benefits and minimize risks. A note: since technology evolves so fast, we try to remain open on what can be achieved with automation and understand that we will have to change our views eventually. And so should your consultancy, as the digital data-driven AEC future is only beginning, we’ll be seeing innovative implementations of technology that go beyond what we are able to think of today.

When starting the journey towards automated workflows, a key aspect is early identification of areas where the most time is wasted on BIM design processes. It might be BIM modelling, geometry, might be structural models, reinforcement modelling, or it could be documentation, information management. Regardless, the key things to look out for, are repetitiveness, likelyhood of human error, uncertainty in the form of multiple required model iterations. In general, from our experience, the most time can be saved during modelling and preliminary modelling stages, with information managent and documentation trailing behind. If all areas are somewhat automated, on average it is possible to reduce the time needed to deliver the project by at least 15-20% and up to roughly 40% (as shown in the illustration below). Of course, these numbers depends on various conditions and will differ from project to project. While it might be possible to go for very high levels of automation to reduce the time spent on projects by even more than 40%, the time required to create such an automated workflow could potentially outweigh the benefits of this. Finding the balance between time spent on developing automated workflows and actually implementing them is a non trivial process, particularly if your consultancy has little experience in this regard.

Benefits are to be had regardless of which project stage is targeted. Starting with BIM modelling is often a good choice, as it can have the maximum potential to reduce overall project time. Improved efficiency in model creation should also cascade quickly to other stages. Company specifics and overall strategy are key in considering which areas should automation be focused on to achieve better results. Each consultancy is different in its own way.

One more thing to consider is whether to go for less but more complex automation tool development or go for multiple tools aimed at smaller tasks. The general advantage of more smaller impact tools over larger complicated ones is reduced risk, in case the tool does not work out or does not deliver the expended outcome. Moreover, we noticed that smaller scale Dynamo scripts are more likely to increase the efficiency and reduce wasted time, with the exception of when highly complicated BIM models are required that are not easily doable with just plain Revit. In those cases, Dynamo can save countless hours. Focusing on smaller tasks initially not only will mitigate risks but will also provide ample time to learn from mistakes and understand better what works and what doesn’t. Initial ideas are often modified to become working solutions, regardless if it is design, coding, engineering, it is best to pace the process naturally. With the adoption of BIM automation through simpler tools, the possibility to collect usage data, statistics opens up, to find out what is used, how it is used by your team and how often. This data can then influence future automated workflows.

With data, proper standardisation, well defined parametric models and developed automation solutions, the next leap is to focus on the previously discussed generative design or application of machine learning to come up with solutions for your BIM problems. These cutting edge tools greatly expand the possibilities and can bring advantages to everyone, from consultants to contractors to clients. The AEC industry will only see the pace of adoption of such innovations increase over time. Invoke SHIFT is a big supporter of digital innovations and the rapid digitisation and automation of the AEC sector, we firmly believe in the synergy between the creativity, potential of people and capabilities of computers and digital technologies. While some think of risks to replacement of people, we see the opposite, the possibility to expand areas and ways in which people can contribute to the AEC sector. AI will greatly impact every consultancy eventually, but in this post, we wanted to remind that there are plenty of steps that have to be taken to get there and proper

Making the most of it

Ultimately, automating BIM tasks is about bringing meaningful impact to the efficiency of your consultancy, reducing the time necessary to carry out certain design, BIM management, or other tasks. Furthermore, due to the inherent relationship between time and quality, a natural uplift in the quality of your company projects is inevitable, through ensured consistency to additional time for engineers to come up with better solutions to problems and more time for architects to express their creativity.

These benefits will come naturally, if the automation process is implemented naturally. Standardisation will bring clarity through rules and boundaries. Quantifying them allows for the creation of parametric BIM models. These prior stages will feed into automation efforts and help your consultancy save time and consistently deliver the neccesary project quality. With proper implementation and sufficient data, application of generative design or advanced AI solutions becomes possible.

Automation ensures that a specific level of quality is consistently achieved in your projects. Properly implemented, it can reduce the

The entire process saves time, which translates into multiple benefits for the consultancy and architects/ engineers. With standards providing rules and constraint the level of quality will be raised for all projects. Automation reduces the time it takes to carry out certain actions and increases project quality through consistency and indirectly through saved time, that can be used by your team to deliver better solutions. Better solutions can further improve your projects and reduce time wasted on

Highlights

- Standardise a set of rules and constraints for your design problem or workflow;

- Quantify the key variables and parameters of your problem and create initial parametric models based on that data;

- Automate your most time-consuming BIM design processes or those that are complex and prone to human error;

- Collect data from your BIM models, from previous projects and establish a system for collecting data in the future, so your consultancy has enough sufficient proprietary data to begin the journey into

data-driven design, from BIM data analytics to the application of artificial intelligence for digital design processes; - Be sure to have established a robust system for each stage before taking the leap into the next one. Approaching data-driven design is impossible without enough data and having automation tools to feed the data into. Design process automation should not be pursued without well developed parametric models and quantified variables/parameters. Which in turn should only be established after other aspects of your company’s BIM modelling workflows are well standardised as to avoid any potential conflicts in the future. Standardisation is the foundations for

a robust and impactful automation of BIM workflows.

Final words

If your consultancy is still to transition to automated BIM workflows, we hope this post can shed some light and provide material to think over. The process should not be rushed and a natural flow of implementing automation is required to avoid common pitfalls and make the most out of it.

Here at Invoke SHIFT, we aim to assist AEC sector companies to transition into the data-driven future, provide support in carrying out complex Revit BIM modelling related tasks, help in deriving actual working BIM strategies and workflows, and most importantly, we aim to increase your teams efficiency and improve your BIM project quality level through automated workflows with Dynamo and Revit API based solutions. If you would like to discuss how we could help you solve your problems, drop us a message either in the contact form below or by

Contact Us

If you would like to get in touch with us, you can do so by filling the form below and we will get back to you as soon as possible. Alternatively, you can email us directly at: